Looptworks FAQs: we provide zero waste to landfill solutions, from the materials we accept to our circular processes and environmental impact. Our commitment to sustainability drives us to create innovative circular solutions that extend the life of textiles and keep materials in use for as long as possible. Through textile circularity, we partner with brands, manufacturers, and industries to recycle excess materials, transform discarded fabrics into new textiles, and supply circular fibers for future use. Whether you’re looking to recycle surplus textiles, reduce waste, or integrate sustainable practices into your operations, our FAQs provide insights into how Looptworks can help you achieve your sustainability goals.

We aren’t hyper-focused on one input and one output. We have tailor-made our process to accept multiple material types on the input side and, therefore, have different product applications on the output side. Our strategic partners send us excess textiles to be transformed into circular fiber/yarn and thus utilized again in their supply chain.

Looptworks accepts a variety of natural and synthetic textile fibers, including cotton, polyester, cotton/polyester blends, nylon, wool, and acrylics.

Looptworks accepts most textiles; however, we do not accept textiles that have contaminants like grease and oil. Looptworks also cannot accept inbound products that have any content that is on a current Restricted Substance List.

While there are no minimum quality standards for input materials, Looptworks will need to know about the material composition of your excess textiles, including any chemical coatings.

Accumulate the minimum order quantity (2,200 pounds, or 1 metric ton) and work with our sales and operations team to coordinate your shipment. Please note we do not accept public drop-offs.

At this time, we do not accept public drop-offs—but this could change in the future, so keep checking back!

We track water and energy conservation as well as carbon avoidance. We provide data based on industry-standard information, recording the actual footprint of virgin versus recovered materials to get a clear illustration of your organization’s impact. We will also report total weight as Landfill Avoidance as a metric.

Our partners include fashion and apparel brands, municipalities, cut and sew manufacturers, and industries such as hospitality, medical, and waste collection. Looptworks also supplies clothing brands, spinning mills, and the non-wovens market with circular fibers to cycle into new materials.

Looptworks is headquartered in Gresham, OR, and works directly with businesses throughout the Pacific Northwest. We also work with a network of partner facilities across the United States to collect input materials. This helps us reach businesses nationwide without incurring the shipping costs and carbon emissions that it would take to deliver excess textiles to our headquarters.

During your initial meetings, the Looptworks team will work to learn about your inventory problem. It’s helpful to prepare a spec sheet that includes the type(s) of excess textiles you have, their material composition, and the location of the textiles. Based on this information, we’ll help you determine the highest-value recycling solution for your input materials. While circularity (via fiber-to-fiber recycling) is our primary objective, downcycling is a zero-waste-to-landfill solution for lower-quality input materials.

Circularity is a system that extends the life of textiles, reducing our need for virgin resources. Through fiber-to-fiber recycling, this system reduces CO2 emissions, water consumption, energy use, and physical waste.

Fiber-to-fiber recycling involves breaking down excess and end-of-life textiles into fibers that can be used to make new garments. The materials used to make new clothes are sourced from existing ones, and end-of-life clothing is a new beginning rather than a waste stream destined for landfill.

Downcycling involves breaking down waste materials into smaller components via mechanical separation. We collect, sort, and open textile fibers used to make non-woven products, such as insulation, carpet padding, concrete binding, and acoustic tiles.

Ideally, they go back into your supply chain, and Looptworks becomes your full-service circularity partner, recycling your excess textiles into fibers that your business can use to make new textiles. We also supply clothing brands, spinning mills, and the non-wovens market with circular fibers to cycle into new materials.

No. From 2009 to 2022, Looptworks focused on upcycling companies’ excess textiles, from airplane seats to NBA jerseys, into quality bags, backpacks, and travel accessories. In 2023, we transitioned to a fully B2B business model, adopting new technology to help companies take their excess textiles circular.

The Loopt Foundation focuses on sharing and building our circularity knowledge with the industry, academia, and the next generation of industry professionals. We’re proactively shaping this expertise into a certification process that guides and verifies brand efforts to close the loop.

Learn more at loopt.org.

Have a question we didn’t cover here? Reach out to Looptworks to discuss what circularity would look like for your organization.

Denine has over 20 years of experience driving new business opportunities for leading companies, including E.I. DuPont de Nemours & Company, Inc., The Dow Chemical Company, Outlast Technologies, and DST Systems. She holds a BS from the University of Pittsburgh and a Certification in Executive Management from the Kenan-Flagler School of Business at the University of North Carolina at Chapel Hill.

Tami is a senior accounting leader with over 16 years of experience in the manufacturing and textile industry. Her specialties include process development and implementation, mergers and acquisitions, job and project costing and analysis, and managing complex teams and technical projects. Tami has served as Chief Financial Officer and Controller for a variety of innovative companies, where her analytical skills and strategic mindset helped organizations create efficiencies in their financial systems.

Kelley is a passionate and strategically minded business development leader with more than two decades of experience in the sporting goods apparel industry. He has experience in product construction, league partnerships, retail relationships, supply chain management, sustainability, circularity, and carbon footprint management. Kelley builds successful partnerships by putting the customer first while simultaneously advancing his organization’s business objectives.

Suzy is a product leader and operations expert with more than 25 years of experience in the textile industry. She is passionate about finding creative solutions to complex problems and motivating people to action through vision, strategy, collaboration, and communication. Suzy has proven expertise in product development, sustainability, marketing, supply chains, and innovating processes and best practices to drive results.

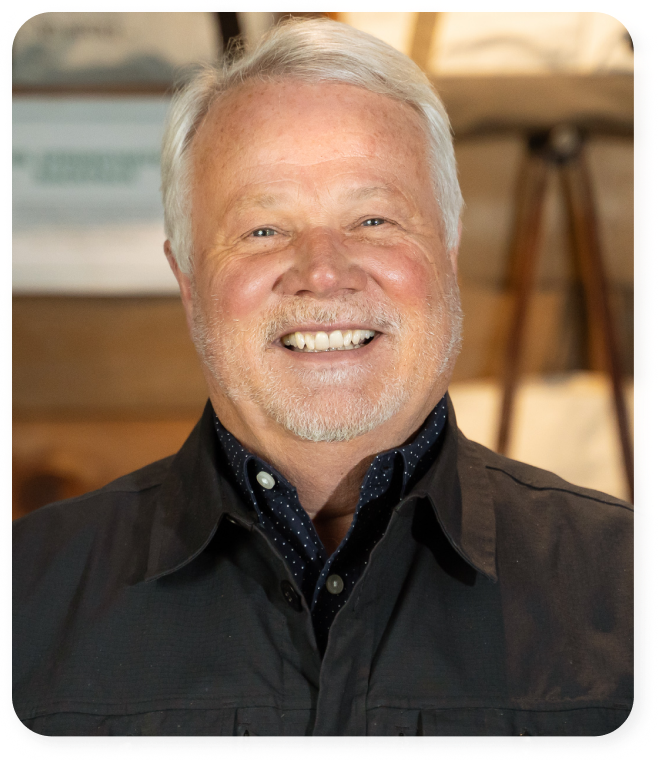

Scott is a visionary leader with more than 32 years of experience in strategic branding, innovative product creation, supply chain sustainability, and sales and marketing for global organizations. He founded Looptworks in 2009 as an industry solution for turning excess materials into upcycled consumer products. In 2022, Scott transitioned the company to a B2B business model focused on eliminating global textile waste through closed-loop solutions.

Scott is a visionary leader with more than 32 years of experience in strategic branding, innovative product creation, supply chain sustainability, and sales and marketing for global organizations. He founded Looptworks in 2009 as an industry solution for turning excess materials into upcycled consumer products. In 2022, Scott transitioned the company to a B2B business model focused on eliminating global textile waste through closed-loop solutions.