In the realm of responsible textile product production, it’s crucial to adopt a holistic perspective that encompasses a product’s entire lifecycle. This involves scrutinizing material sourcing, manufacturing processes, composition, and, most importantly, the fate of a product once it reaches the end of its useful life within the context of textile circularity.

Circularity, at its core, entails a comprehensive approach, ensuring every stage of a product’s existence is considered to prevent it from languishing in landfills indefinitely.

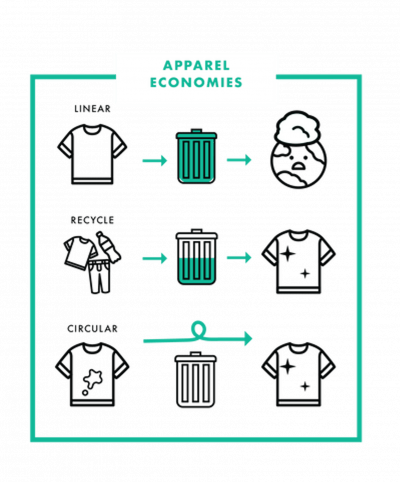

The Linear System: Take, Make, Waste Circularity emerges as a response to the prevailing linear system of production, where products are mass-produced with virgin materials, leading to a majority finding their way to landfills. This wasteful process extends beyond the final product, as excess materials generated during production often end up in landfills without ever being utilized.

Fast fashion epitomizes the drawbacks of the linear system, churning out an immense volume of disposable goods that contribute significantly to environmental degradation. This has a severe impact on our climate, with millions of tons of pollutants infiltrating the atmosphere and oceans annually.

Enter the Circular System The circular system is an antidote to the linear model. In this paradigm, used, damaged, and excess materials and products are diverted away from landfills and reintegrated into the supply chain. The methods of reintegration vary depending on the condition of the materials.

Downcycling Materials that are no longer structurally sound for recycling can still be repurposed for extended use. Shredded damaged or excess materials find new life in construction, contributing to insulation, building foundations, and road creation.

Plastic to Fiber Recycling The trend of creating clothing from recycled plastic bottles has gained traction, with various brands championing this sustainable approach. The process involves breaking down plastic bottles to a molecular level, reforming them into spinnable fibers. While preferable to using virgin materials, it poses challenges for subsequent recycling due to weakened fiber strength.

Upcycling Utilizing high-quality pre- and post-consumer excess materials, such as fabric spools or leather offcuts, presents an alternative to disposal. Products that are damaged or unsellable can be deconstructed and transformed into new items through upcycling, the most eco-friendly option for reuse.

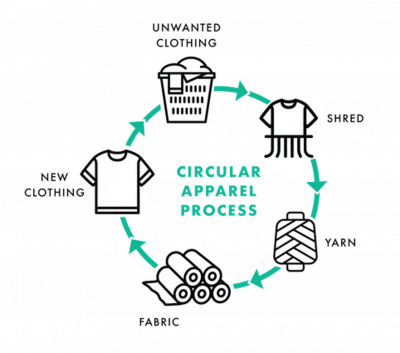

Fiber to Fiber Recycling In the realm of apparel, fiber-to-fiber recycling emerges as a pivotal strategy for ensuring clothing stays out of landfills indefinitely. Circular apparel utilizes fibers that can be endlessly recycled into virgin-quality fibers, creating a closed-loop system. Looptworks is pioneering the establishment of the first fiber-to-fiber recycling facility in the US, envisioning it as a sustainable textile production hub.

Calling All Businesses with Excess Textiles If your business deals with excess textiles, our solutions team is eager to collaborate! Together, let’s weave a greener tapestry for generations to come.

We’d love to hear from you!

Tami is a senior accounting leader with over 16 years of experience in the manufacturing and textile industry. Her specialties include process development and implementation, mergers and acquisitions, job and project costing and analysis, and managing complex teams and technical projects. Tami has served as Chief Financial Officer and Controller for a variety of innovative companies, where her analytical skills and strategic mindset helped organizations create efficiencies in their financial systems.

Kelley is a passionate and strategically minded business development leader with more than two decades of experience in the sporting goods apparel industry. He has experience in product construction, league partnerships, retail relationships, supply chain management, sustainability, circularity, and carbon footprint management. Kelley builds successful partnerships by putting the customer first while simultaneously advancing his organization’s business objectives.

Suzy is a product leader and operations expert with more than 25 years of experience in the textile industry. She is passionate about finding creative solutions to complex problems and motivating people to action through vision, strategy, collaboration, and communication. Suzy has proven expertise in product development, sustainability, marketing, supply chains, and innovating processes and best practices to drive results.

Scott is a visionary leader with more than 32 years of experience in strategic branding, innovative product creation, supply chain sustainability, and sales and marketing for global organizations. He founded Looptworks in 2009 as an industry solution for turning excess materials into upcycled consumer products. In 2022, Scott transitioned the company to a B2B business model focused on eliminating global textile waste through closed-loop solutions.

Scott is a visionary leader with more than 32 years of experience in strategic branding, innovative product creation, supply chain sustainability, and sales and marketing for global organizations. He founded Looptworks in 2009 as an industry solution for turning excess materials into upcycled consumer products. In 2022, Scott transitioned the company to a B2B business model focused on eliminating global textile waste through closed-loop solutions.